Bell ropesAll our bell ropes are hand made to order on our rope walk in Bristol and can be supplied with four different types of top end:

UHMPP - Ultra High Modulus Pre-Stretched Polyester. This is our own in-house development of a product guaranteeing a very low stretch of bell rope, with the added benefit that they can be quieter than a normal 3 stranded rope. Natural top ends are available with the full length however we normally recommend that ropes longer than 40ft (12m) use pre-stretched polyester top ends due to the much improved wear characteristics and reduced influence from atmospheric conditions. Pre-stretched polyester top ends are by far our most popular top end choice, they offer a low stretch solution for towers with a medium length draft. Pre-stretched polyester top ends have been used for bell ropes since the 1980s due to the better wear characteristics around pulleys and garter holes, but also it does not shrink and get stiff in damp weather and get longer and looser in dry weather, unlike natural fibres. Every batch of pre-stretched polyester rope we purchase is made to our own specification and we check the quality against our own standards. This ensures that we can provide the customer with the highest quality product and gives us the confidence there will be no issues with ‘stretchy’ ropes. The polyester is machine spliced into the rope about 0.92m (3ft) above the sally. We can reduce the length between the sally and machine splice if needed. We are the first company to have developed and Patented this technique required for an elegant splice between a braided rope and natural 3 stranded rope. When required, we make our Yorkshire Tail ends to the "The slimline Yorkshire Tail end" specification. A copy of the specification is here courtesy of the Whiting Society. Our ropes are not designed or intended to undertake any lifting, pulling, or supporting of loads or people, they are designed to be control lines to enable ringers to control the bells. They are NOT load tested or certified to meet any lifting of load regulations (e.g. LOLER). Dyneema® and UHMPP rope on a roll

|

The SallyThe sally is the asset in the bell rope, it is what makes the difference between a rope and a bell rope.

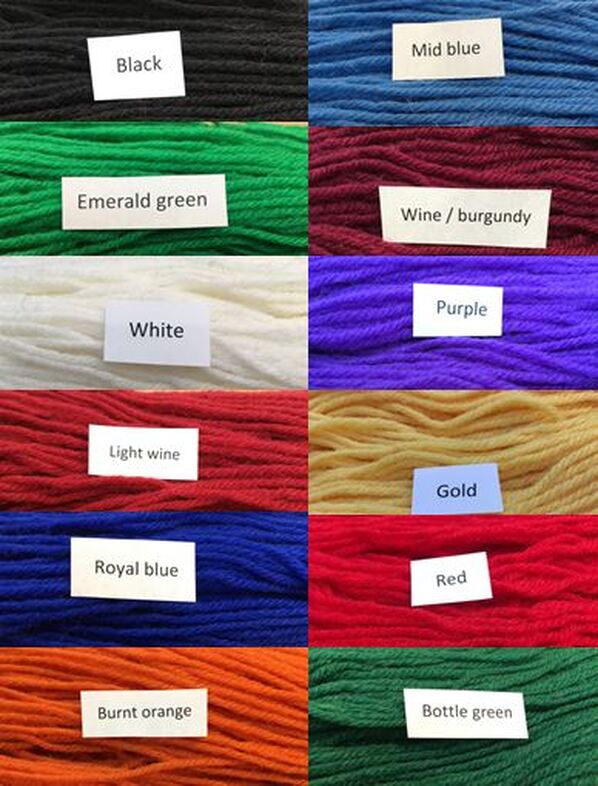

We manufacture new sallies in-house and can repair existing sallies with entirely new tail ends and top ends - please see our repairs page. We have manufactured bell ropes with sallies from everything between a few centimetres to 1.8m (6ft). The following choice of wool colours are available for sallies: All of our full-sized bell rope sallies, as standard are trimmed to approximately 1 7/8” (47mm) diameter. They are graded, and the heavier gauge of ropes are provided with a slightly bigger diameter sally. We have the following British wool colours available; Should you require a colour sample please contact us Our sally cutting system is fully adjustable to accurately finish sallies in a range of different sizes. Our standard sally sizes are below;

Our standard sally length is 3 feet (915mm) and we offer sally lengths in 6” inch (150mm) increments from a few inches up to 6 feet long (1.8m). Our Yorkshire Tail ended sallies are the thinnest of sallies we do for full sized bell ropes at 1 ½” (38mm) diameter sallies. The sallies are also longer at 40” (1m) long. We have made many Yorkshire tail ends of the modern slimline Yorkshire tail end design. Our rope thicknesses are made to a standard gauging chart, which has traditionally been used for bell ropes for many years relating to the bell weight. There is a close approximation between the gauge to a diameter, but the gauge is not a measure of the diameter. Commonly, there are 8 different gauges used for bell ropes. Over time and with use, natural fibre tail ends get slightly longer and thinner. The traditional bell rope scale of gauges uses characters such as 2F, G3, F3 etc, please see our FAQ page for more info on gauges. . |